Tools and accessories

Highly efficient mass property measurements aided by optimized equipment.

Highly efficient mass property measurements aided by optimized equipment.

Highly efficient mass property measurements aided by optimized equipment.

All Resonic machines have crane interfaces (except for small Resonic machines, which can be easily lifted by hand).

Optionally, the machines can be equipped with extendable castors so they can be moved without any additional tools.

Optionally, the machines can be equipped with rigid covers to protect the machine when it is not being used.

Optionally, Resonic can provide a flight case or transport box that makes it possible to move the machine between facilities (e.g., by truck) or to safely move the machine into storage (e.g., with a forklift).

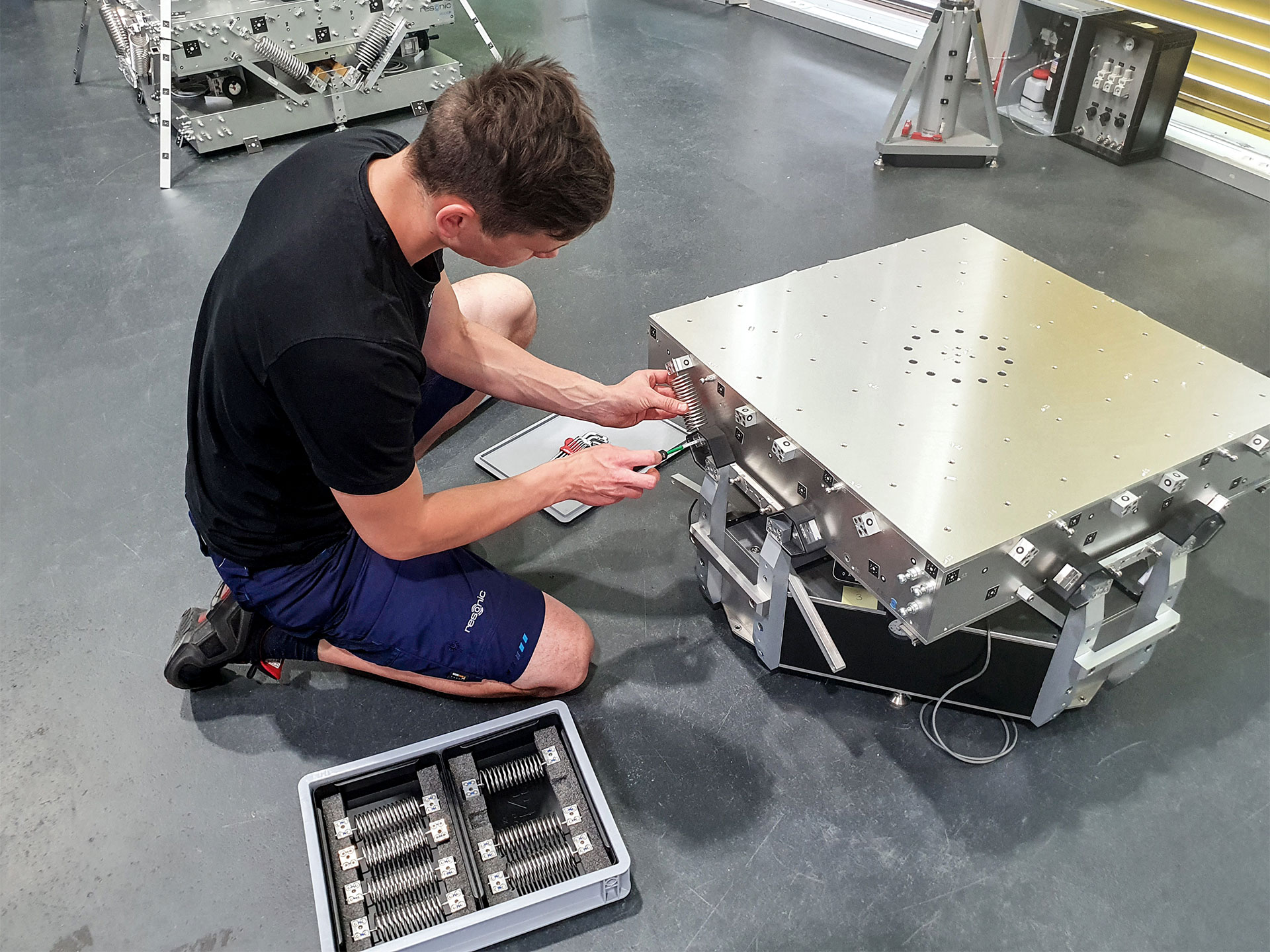

Resonic MPM systems include all the necessary tools and accessories for operation of the machine, including tools to adjust the machine’s feet, crane interfaces, transport locking components, scales, exchangeable springs, and spare air filters. The accessories are usually organized in boxes with machined foam inserts. There are several options for storing the boxes, including the following:

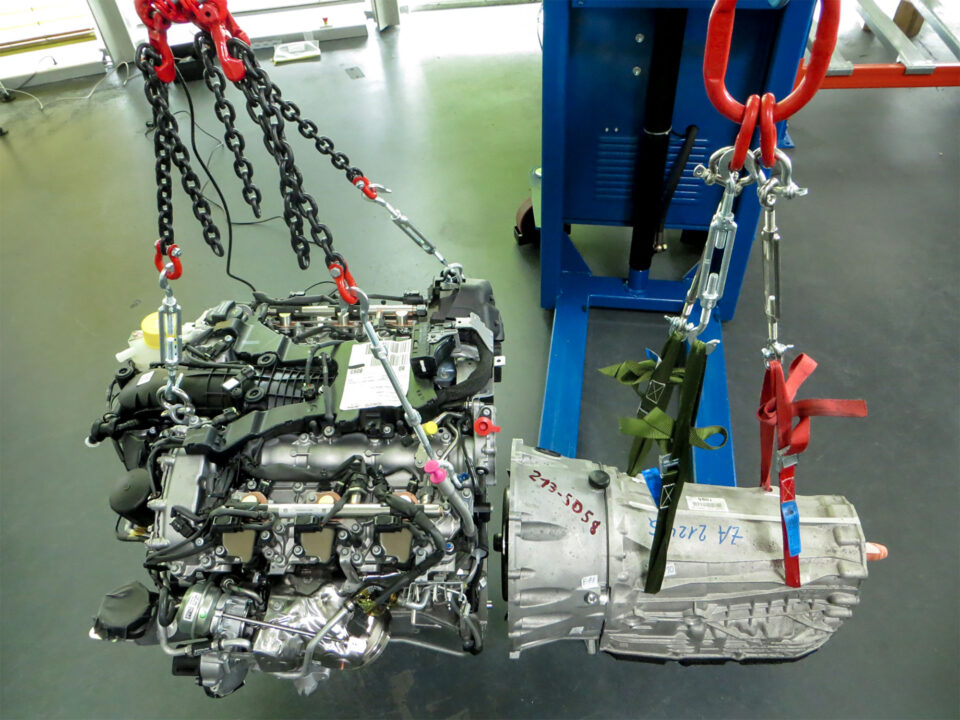

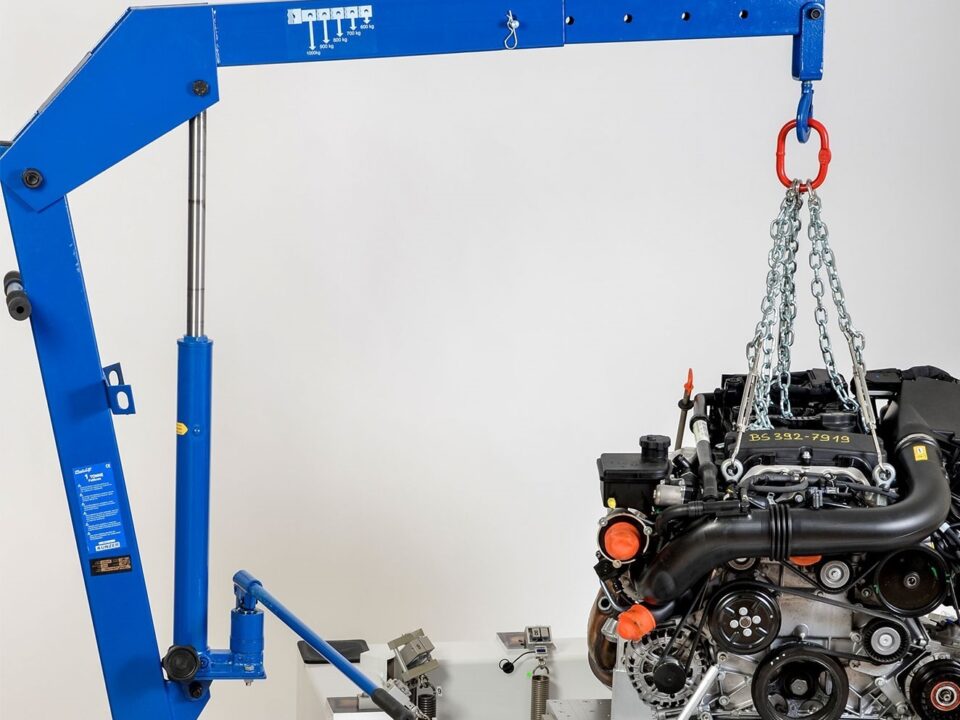

Resonic can provide or recommend various solutions for lifting and positioning the test object, such as the following:

Except for Resonic S, all Resonic machines use air-bearing technology. Our systems always include the components necessary for operating the air bearings: filters, dryers, pressure regulators, valves, and tubes. In some cases, these components are integrated into the machine, and in other cases, they are contained in external units.

The air preparation units are compatible with almost any modern factory air grid. If no factory air is available, oil-free compressors can be used. Resonic can supply a suitable, very quiet compressor upon request.

If necessary, Resonic can supply various weighing solutions for determining the mass of the test object and fixture components. Resonic’s preferred solution consists of a conventional platform scale or crane scale, a set of calibration weights, a USB interface (which is compatible with multiple scales), and Resonic’s own weighing software. This solution has several advantages: