Welcome to Resonic

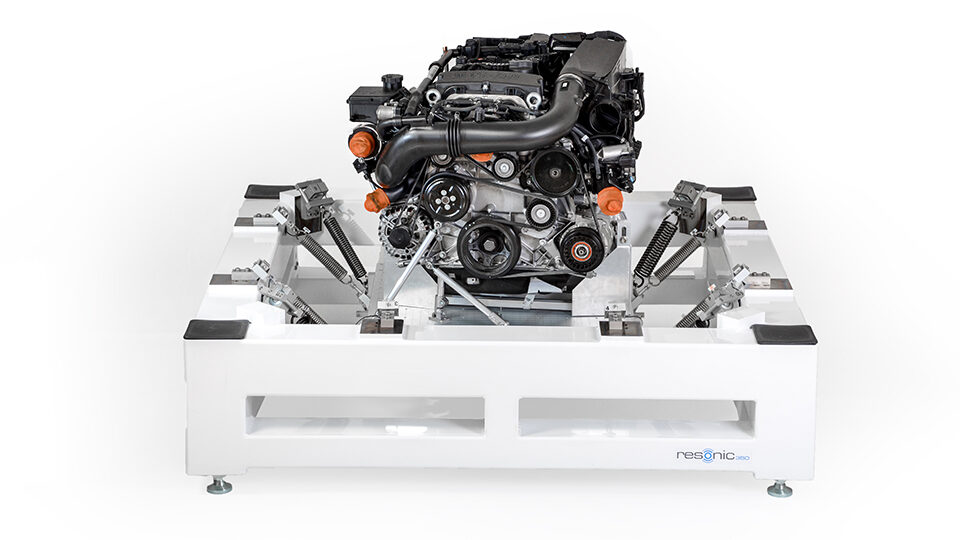

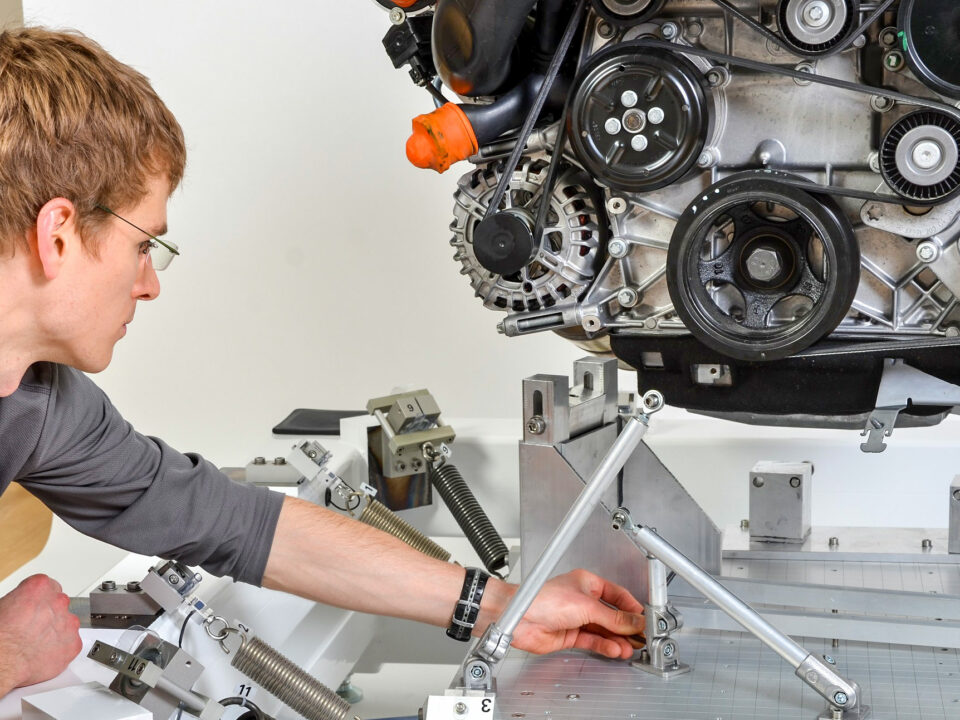

on Resonic-6000F measurement system

allow developers to predict the dynamic behavior of objects in 3D space

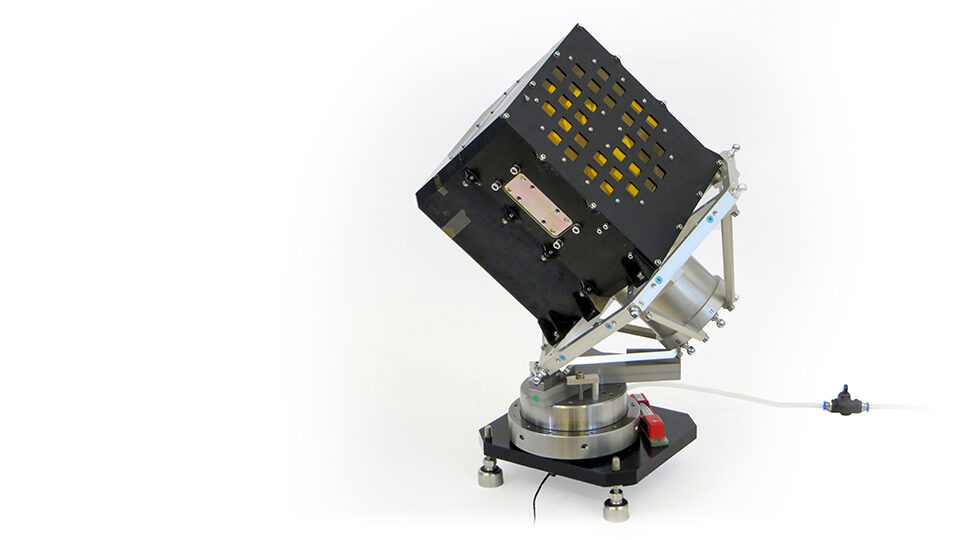

Resonic has a solution for almost any test objects ranging from a few grams to more than 20 tons, from tiny optics modules to engines, motorcycles, cars, ship models and boats, helicopters, all types of satellites, and ultra-heavy vehicles.

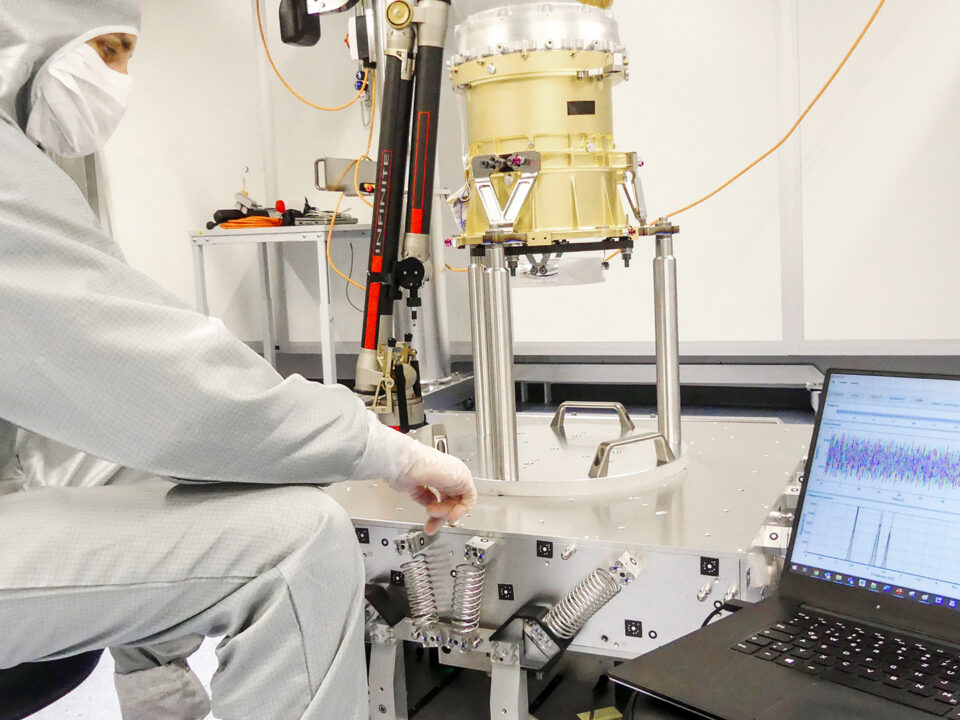

After a few hours of training, the operator is capable of measuring complete mass properties accurately, quickly, safely, and reliably. The preparation work is kept to a minimum because the object is measured in a single, freely chosen position.

Resonic systems are compact and easy to transport, and they require no particular infrastructure. This allows us to offer measurement services not only at our facilities in Berlin and Yokohama, but also at customer sites throughout Europe and Japan.

Our interactive software guides the operator through the measurement process. Full automation is available as an option. Human errors are unlikely and easy to catch due to the quality indicators displayed by the software.

Resonic systems can measure the complete mass properties of large objects on a measurement platform that remains horizontal throughout the measurement process. There is no need to tilt a large satellite or helicopter by 45° or 90°. Additionally, the accelerations are so small that clamping is usually unnecessary.

Over more than a decade, Resonic has gained hands-on experience designing, curating, and optimizing accessories as well as calibration methods, lifting tools, fixtures and adapters, storage and transport solutions, and coordinate transformation methods based on 3D measurements.

Sentinel 1-D Satellite

Sentinel 1-D Satellite

Juice Spacecraft

Juice Spacecraft

Metop Satellite

Metop Satellite

Metop Satellite

Metop Satellite

Metop Satellite

Metop Satellite

ReFEx Rocket / Re-Entry Segment

ReFEx Rocket / Re-Entry Segment

Scaled Flight Demonstrator (SFD)

Scaled Flight Demonstrator (SFD)

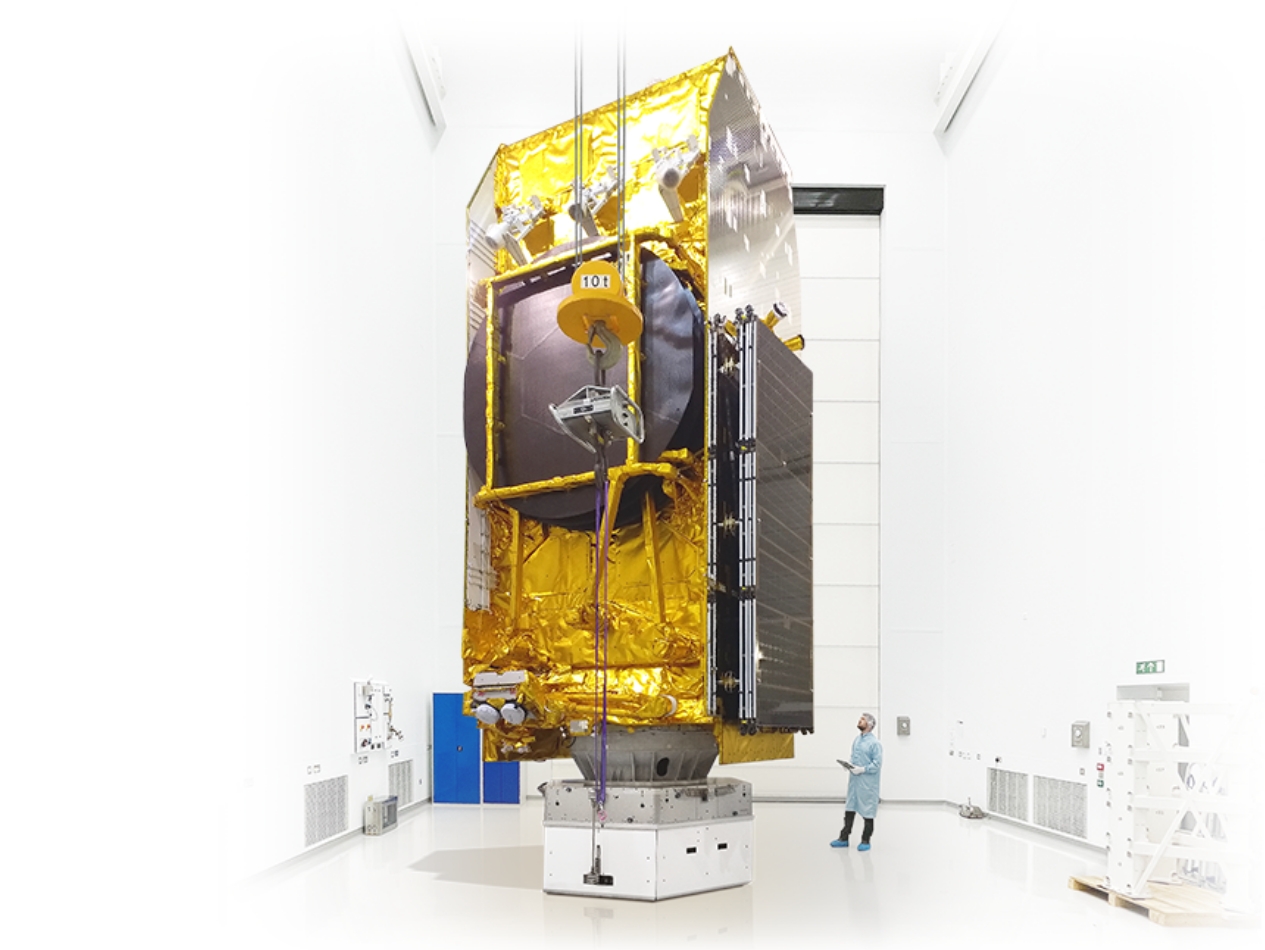

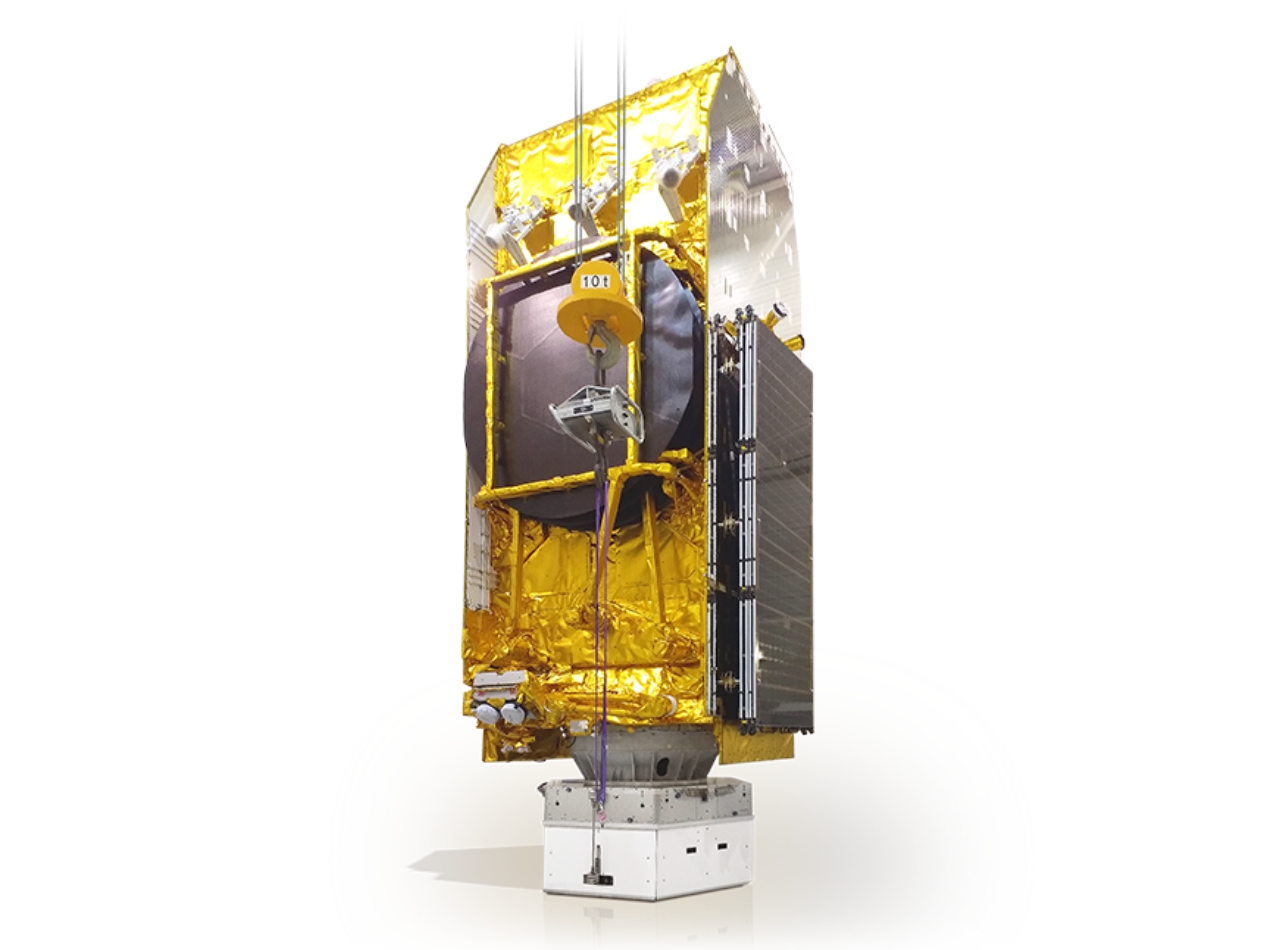

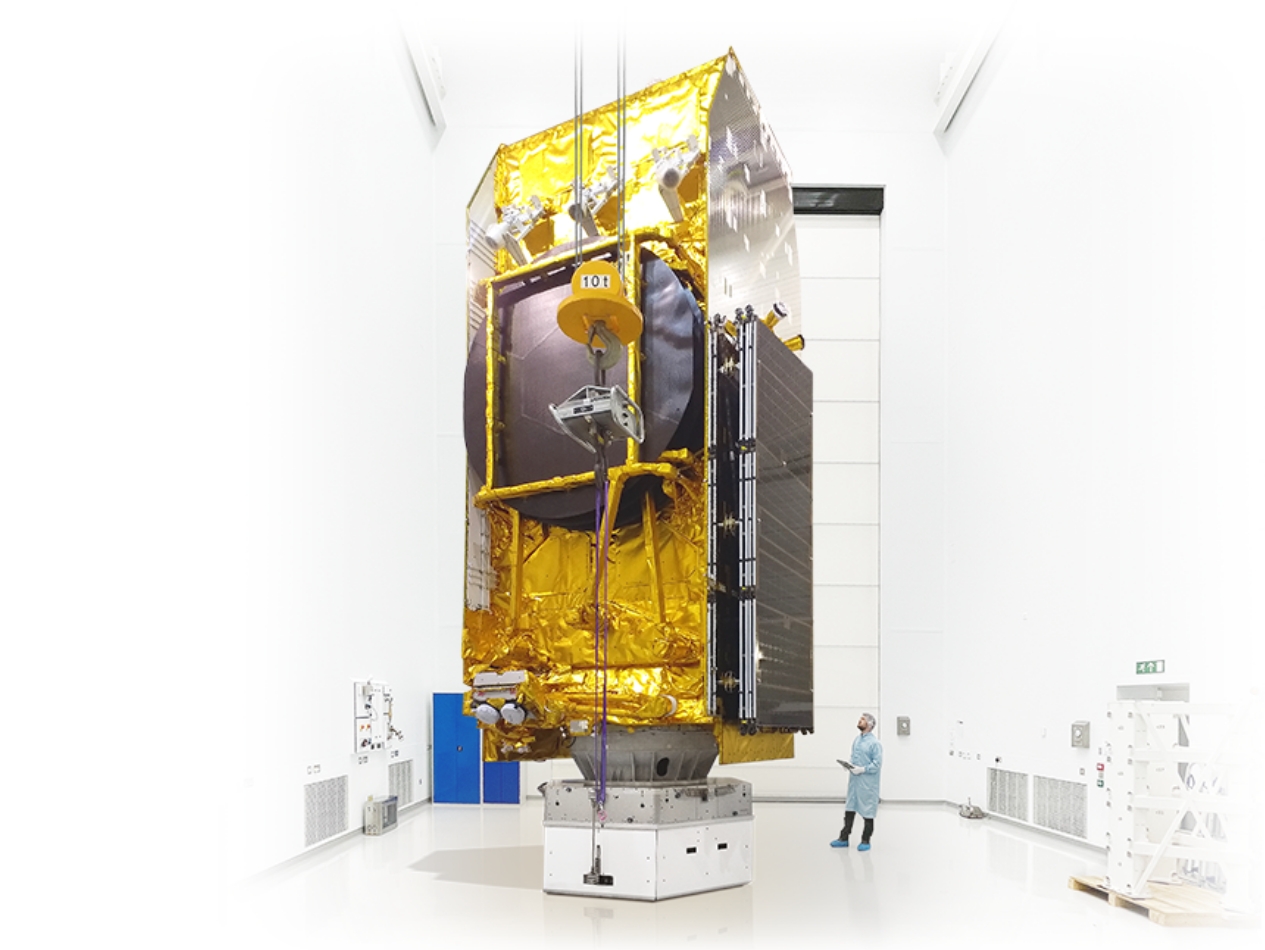

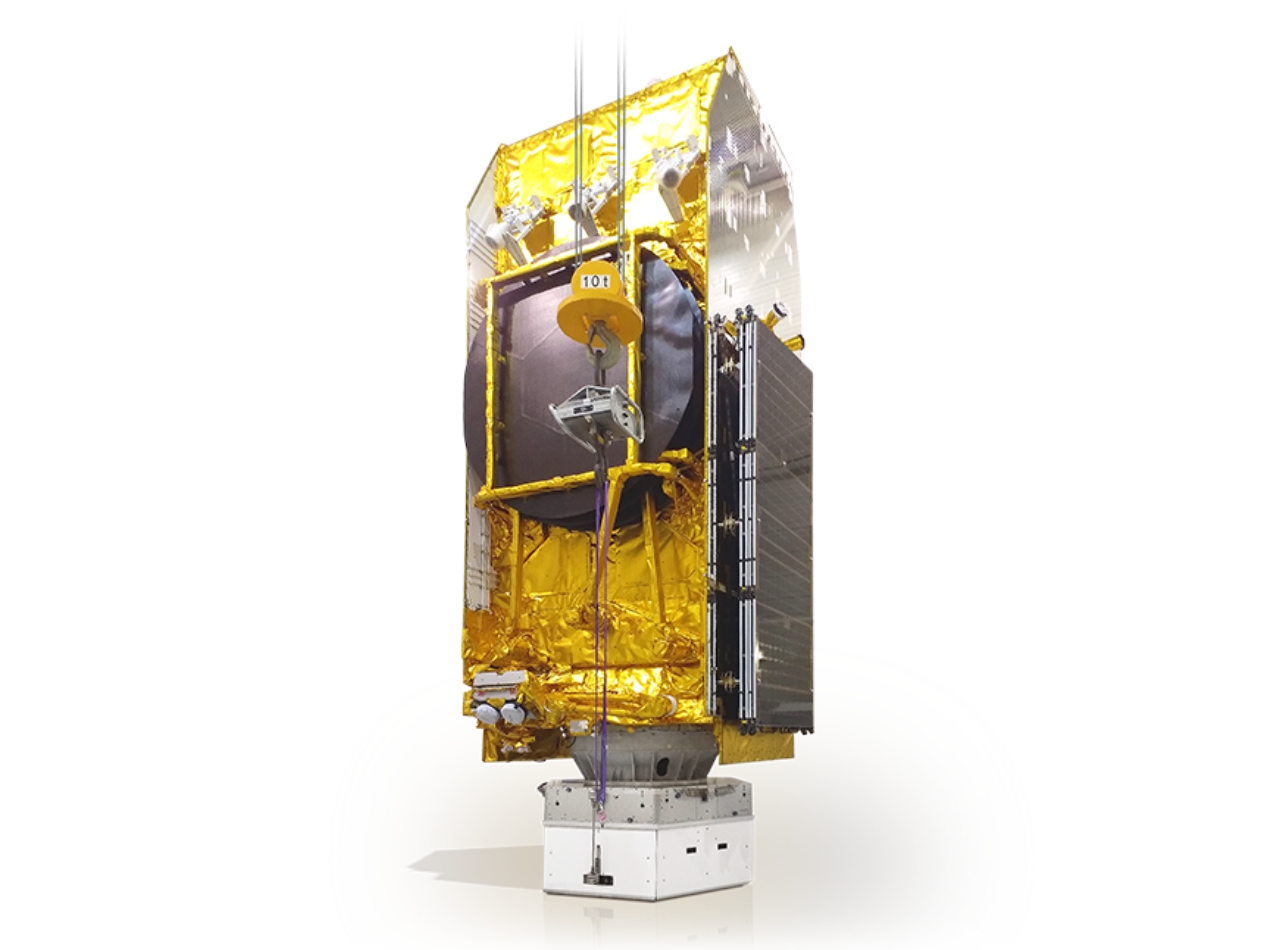

HotBird-F1 Satellite

HotBird-F1 Satellite

HotBird-F1 Satellite

HotBird-F1 Satellite

MicroCarb Satellite

MicroCarb Satellite

Proba-3 Occulter Spacecraft

Proba-3 Occulter Spacecraft

PLATO Telescope Optical Unit

PLATO Telescope Optical Unit

6000F calibration at RAL Space

6000F calibration at RAL Space

500F installation at University of Tasmania

500F installation at University of Tasmania