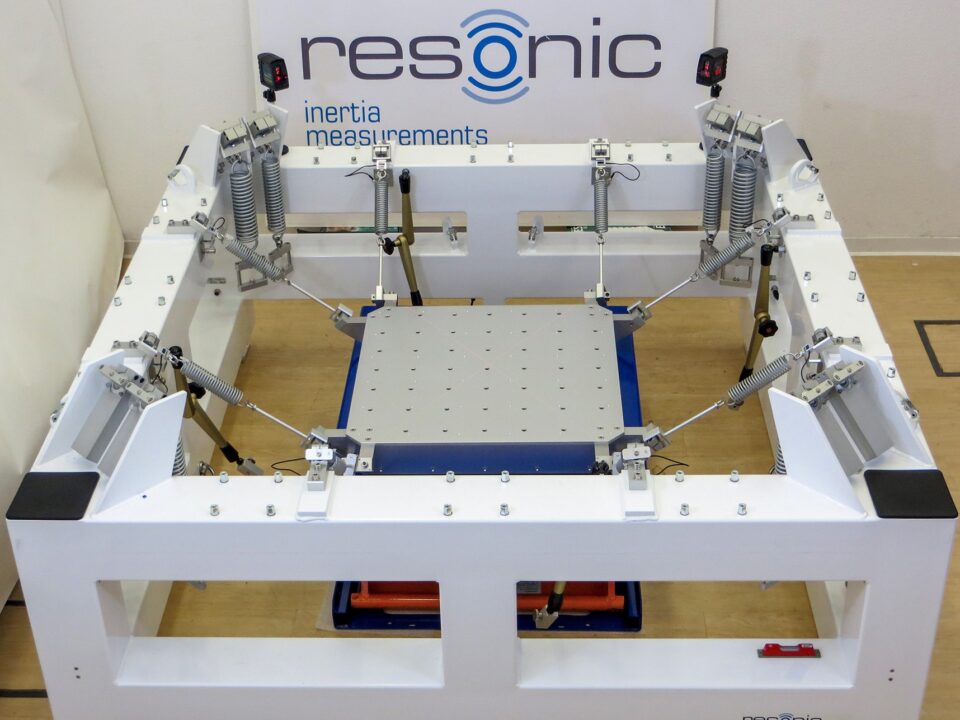

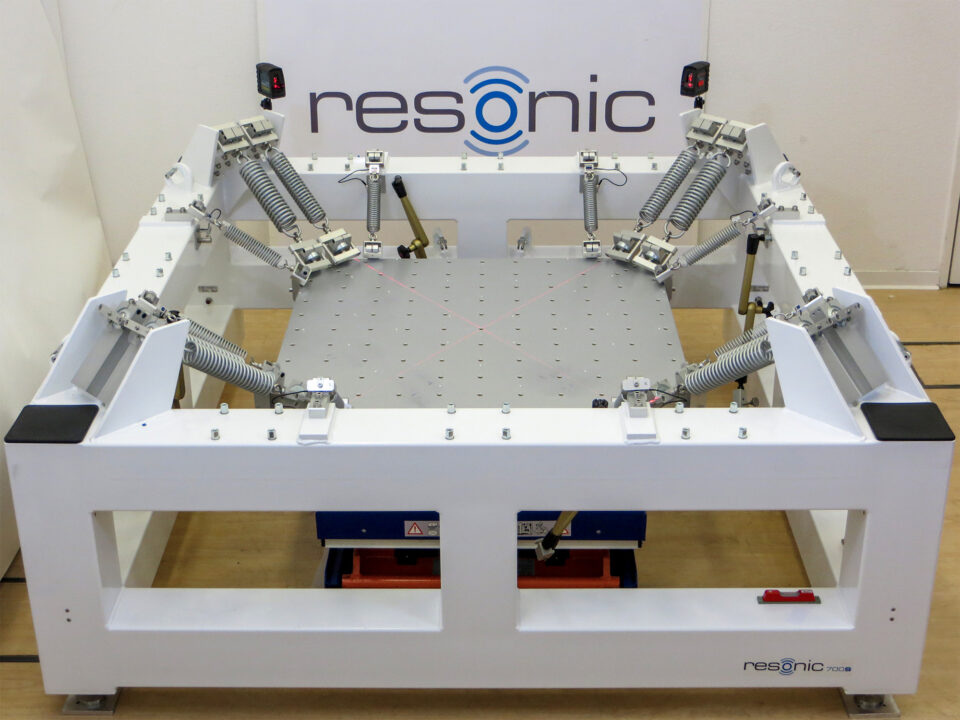

Resonic S is the original Resonic technology and is the best embodiment of our philosophy: very simple and robust hardware combined with a fast, easy, and failproof measurement process. Made possible by sophisticated software.

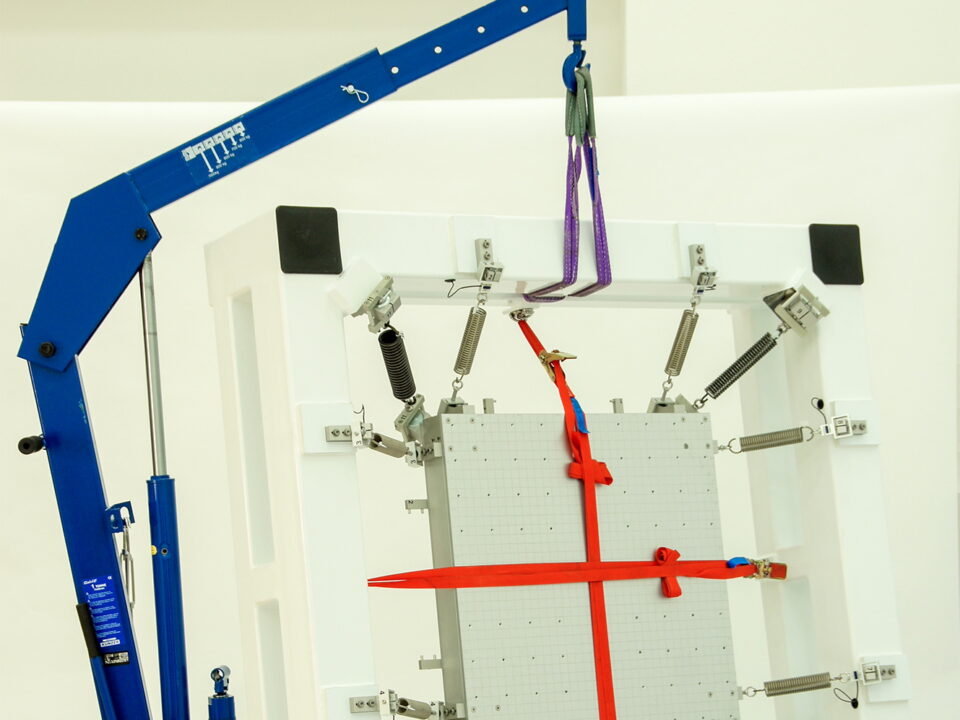

Full MPM results are available within minutes after setup through a simple and failproof process. There is no need to reposition the test object multiple times.

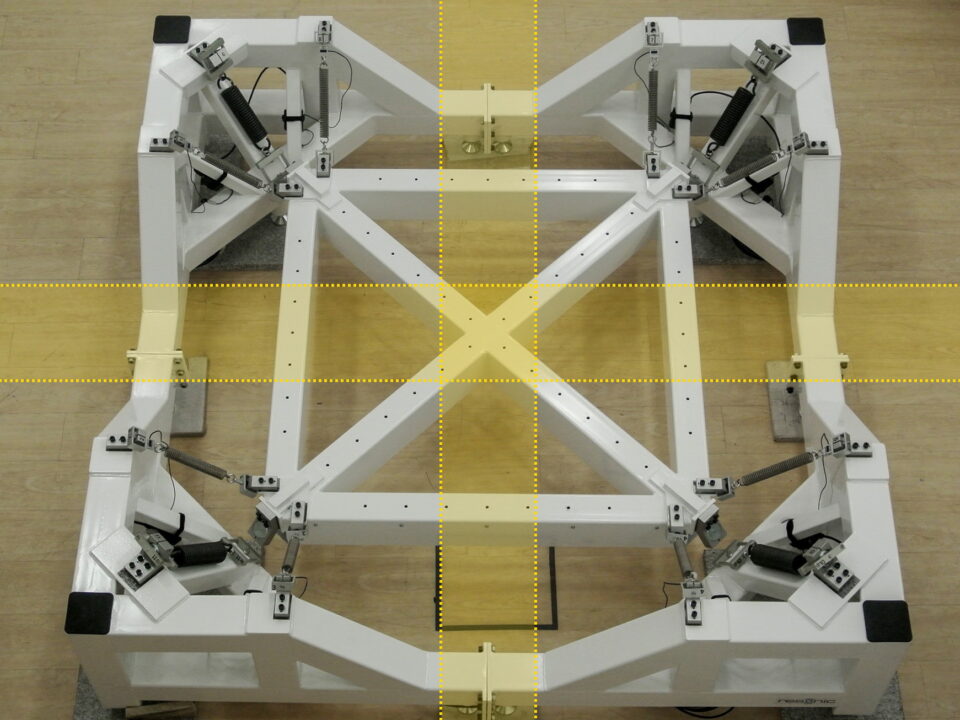

Simple and robust mechanical components guarantee a long lifetime with minimal maintenance.

The hardware and measurement process are characterized by unparalleled simplicity. The complex part is mass property computation based on randomly excited free vibration signals. However, all computations are automatically handled by the software, providing the operator reliable feedback about data quality.

Combustion engines, gear units, differential gears, electric motors, battery units.

Doors, tailgates, engine hoods.

For trucks, cars, and other vehicles.

Washing machine drums, oil and gas drill bits.