Measurement services

For almost any kind of test object with the measurement systems in our product portfolio.

For almost any kind of test object with the measurement systems in our product portfolio.

For almost any kind of test object with the measurement systems in our product portfolio.

Resonic offers mass property measurement services for almost any kind of test object with the measurement systems in our product portfolio.

Thanks to the mobility of our MPM systems, we are able to offer efficient measurement services not only at the Resonic facilities in Berlin and Yokohama but also directly at customer sites anywhere in Europe and Japan. There is no need to ship fragile, time-critical, or confidential test objects.

Once the test object is installed on the platform, Resonic systems are capable of measuring full mass properties within minutes. As a result, we are able to offer fast and economical configuration measurements of, for example, a vehicle both with and without passengers, luggage, or fuel.

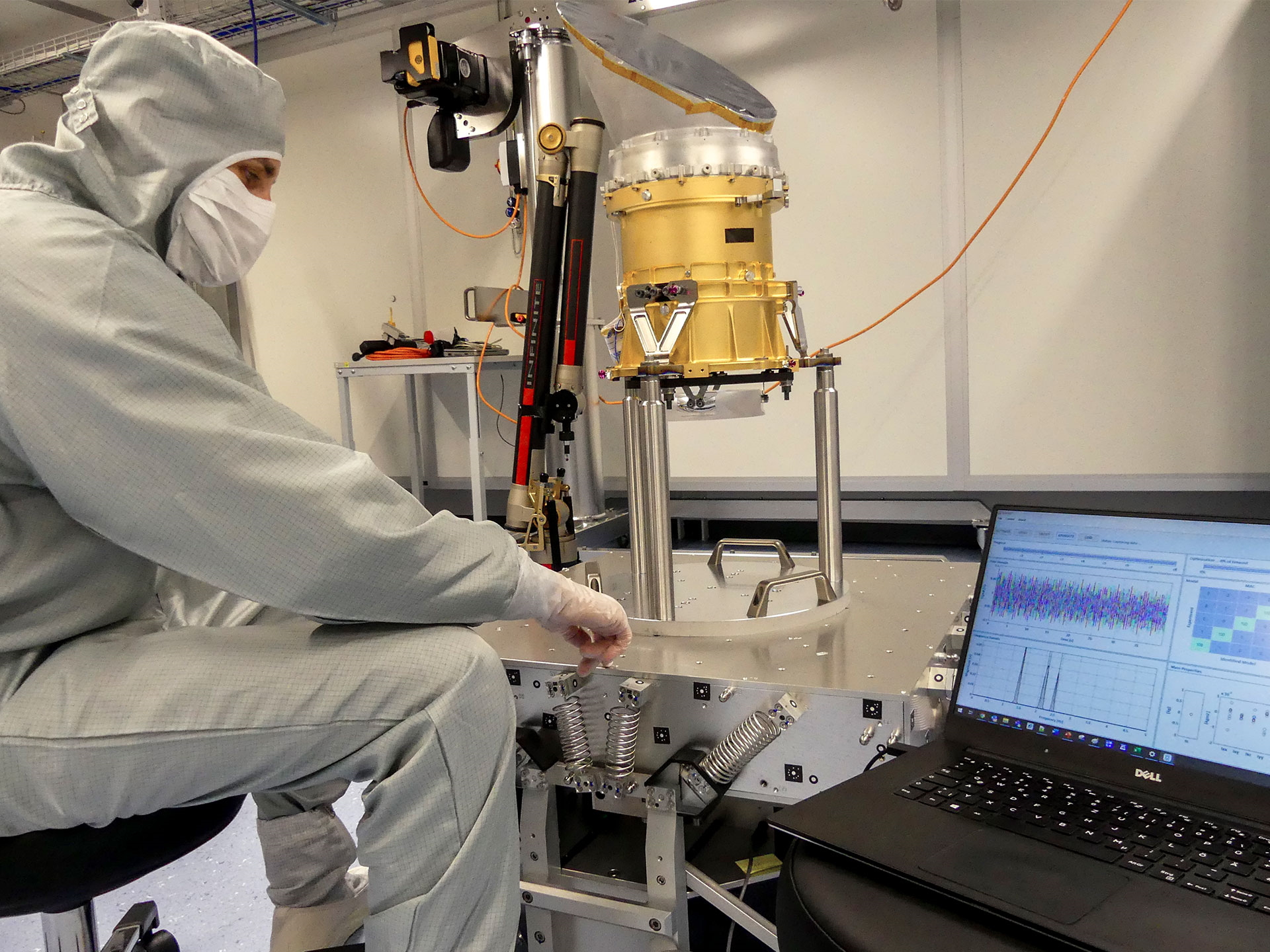

Whether on site or at our facilities, Resonic can provide all the equipment needed for measurements, including an MPM device, lifting tools, 3D measurement system, fixtures, or adapters. An experienced Resonic engineer sets up the equipment and performs the measurements.

Our measurement service equipment includes machines from our own product range, which cover almost any test object between a few grams and 3 tons. To interface the test object, we have adapters for passenger cars, truck cabins, and motorcycles as well as an extensive collection of modular fixtures.

Resonic customers choose our measurement services for a variety of different reasons. Below are a few examples.

Our Formula 1 customers have short time windows in which MPM for their newest vehicle is possible. Within a few hours on site, Resonic measures 2–3 configurations and the vehicle is free for other activities.

High accuracy is maintained over a particularly wide measurement range, even for oblong objects where three very different MOIs must be measured simultaneously.

A small manufacturer needs to measure the mass properties of a new engine model only once or twice per year, so buying an MPM system would not be economical. Instead, they send the engines to Resonic.

Resonic is frequently asked to measure satellites or their sub-systems inside customers’ cleanrooms. Our on-site service removes the risk, cost, and delay associated with shipping the test object to an outside facility.

When the test object needs to have specific mass property values, Resonic measures the current mass properties, the customer attaches suitable trimming masses, and Resonic confirms the result with a second measurement. The test object remains on the machine the whole time.

A customer needs mass property data for a particular R&D project. Two Resonic engineers measure dozens of drill heads ranging from 20–600 kg on site within three days by simultaneously using two different machines.

Instead of measuring a satellite in all its configurations and states of deployment, Resonic could measure two base configurations using a large machine and the solar panels using a small machine. Combining the results through coordinate transformations yields all the configuration mass properties.

A large satellite test center has an MPM system, but it is too large for satellites below 300 kg. Resonic’s on-site measurement service fills this gap.

An overseas OEM is interested in the mass properties of particular car models made by European competitors. Resonic finds and rents these vehicles in Germany and measures the mass properties.

A manufacturer asks Resonic to conduct a large MPM series of 100 objects for a quality control application. Based on the results, management will decide whether to adopt the procedure and purchase their own system.

Connecting oddly shaped test objects to the Resonic measurement platform often requires fixtures or adapters. Resonic can provide the necessary components for every measurement service:

If the measurement takes place at the customer’s site or if the measurement is particularly time-critical, Resonic needs information about the test object’s interfaces ahead of time, ideally in the form of pictures, screenshots, drawings, or CAD models.

→ Click here for more details about fixtures and adapters.

After mass property measurement, the test object is removed, while the fixture components remain in place on the measurement platform. A second “empty” measurement is performed for the fixture mass properties and the result is subtracted from the overall mass property result.

At locations near Berlin or Yokohama, our engineer may arrive in a van and bring the MPM machine and all the auxiliary equipment. Otherwise, our logistics partner delivers one or two pallets ahead of time and the engineer arrives by train or plane.

On location, all we need is:

Once the pallets are moved to the work area, unpacking and setting up the measurement system takes about two hours.

Yes, Resonic measurement services always include a coordinate transformation into the test object coordinate system chosen by the customer.

The coordinate transformation is based on 3D measurements, which Resonic performs with a 3D measurement arm or a photogrammetry system.

The following information must be provided by the customer (if possible, before the measurement starts):

Option 1: CAD-based definition of the coordinate system

The customer provides the CAD coordinates of geometric features, like holes, pins, or planes. The features should meet the following criteria:

Three geometric features are sufficient, but for the sake of redundancy, ideally, more than six features should be measured.

Option 2: Direct definition of the coordinate system

In the event that no CAD data exists (e.g., in benchmarking), the coordinate system can be defined in any other way, such as in the form of a verbal description:

→ Click here for more information on coordinate transformations.

Option 1: Direct method

Ideally, configurable sub-units are added or removed while the test object remains in the same position on the machine. If that is feasible, there is no need for a new 3D measurement or a new empty measurement.

Option 2: Sub-unit combination method

Instead of measuring a test object in all of its possible configurations, Resonic can measure the configurable sub-systems separately and, if necessary, on smaller machines. Then, the mass properties are combined through coordinate transformation into the base-unit coordinate system. This process has the following advantages:

Examples include passenger dummies in various seats of a vehicle, motorcycle luggage, or satellite solar panels in various states of deployment.

The sub-unit combination method is possible even if there is no CAD data available for sub-unit coordinate transformations. Resonic can measure the position of each sub-unit relative to the coordinate system of the base configuration with the help of temporary 3D markers.

After the measurements have been completed, our engineer makes a project file that links to the raw data from the test object measurement, the empty measurement, and the 3D measurement. Then, the Resonic software automatically processes and combines these three data sets and generates a PDF result report. The results are always given as test object coordinates.

Automating processing and report generation is important because it avoids human errors, which may arise when handling the data. It also ensures that reliable results can be provided immediately after measurement. Nevertheless, our engineer double-checks all the quality indicators displayed by the software during the measurement and during data processing in order to make sure that everything has worked correctly.

In addition to the automated result reports, Resonic prepares documentation of the measurement process in case the customer cannot be present during the measurement, on the condition that taking pictures is permitted.